Whether you currently use glass bottles and glass jars for your product packaging or are researching packaging options, you may have questions about the use of glass and its advantages and complexities. These questions are usually structured as Frequently Asked Questions, short as FAQs. Here list a series of answers to some of the FAQs related to glass bottles and glass jars. If the following list of frequently asked questions does not answer your questions related to glass containers, please do not hesitate to contact us for additional assistance.

The main components of the glass

- silica (sand with particular features), which is the glazing element;

- soda, which is the melting element;

- calcium carbonate, which is the stabilizer.

Are all glass recycled?

For the most part, glassware that is used in the kitchen and for food items is completely recyclable. Items such as condiment containers, food storage, jars, and more can be put in your recycling bin. However, not all glass is the same. These two glass that Cant’t be recycled:

- Ceramics

Items made of ceramic appear to be similar to glass, but they are actually made of clay. The reason glass can be recycled is that the glass can be melted down again and shaped into something new. With clay, you cannot melt it down.

- Decorative Glass

Glass that has been painted, colored, or has foiling on it cannot be recycled. This is because the decorative features are not recyclable when mixed with other glass. Once the glass gets to the plant, it is melted down for other purposes.

Why do bottles and jars have thick glass bottom?

The extra thick glass on the bottom of glass bottles and jars is primarily for aesthetic reasons to make the bottle look more valuable, and in the case of clear glass, to enhance the transparency and purity of the bottle.

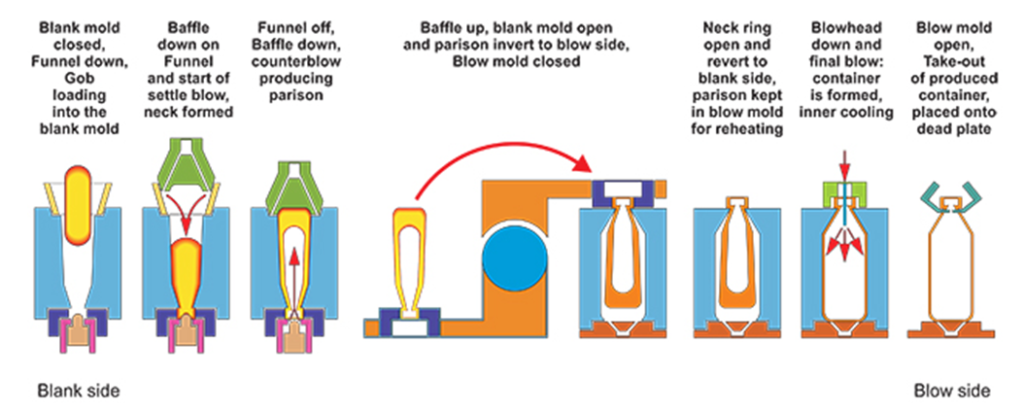

Technically, the concentration of glass on the bottom of the bottles is achieved by creating a special preparatory mold (parison) with a higher glass mass than that of a normal bottle, that does not get deformed during the first blowing process.

What are the advantages of glass compared to plastic?

If you ask a “glass-manufacturer” this question, you’ll immediately get a smile of satisfaction. Glass is the only material which combines qualities that make it suitable for containing food while respecting the environment at the same time: it is waterproof and gas-proof, neutral (physically and chemically), inviolable and totally recyclable.

Why is glass the most hygienic material for packaging purposes?

Because glass is completely neutral to its content: it neither releases anything nor absorbs anything from the product (taste, odor or aroma). It has a high chemical resistance and is waterproof and gas-proof. It can be easily sterilized, has antistatic properties and does not pollute the environment. It is completely indifferent to climate variations.

Is glass “biodegradable?”

No. Glass is a mineral and the labels on glass containers generally state “please dispose of responsibly”. Over time, the glass will tend to “return to sand”, especially if it is thrown away on beaches, in the sea or wherever it may be repeatedly moved by natural elements.

Why does hot water cause glass to break?

It is not the hot water that breaks the glass, but the sudden change in temperature, causing internal stress to be exerted on the material; if these changes occur suddenly, they create internal tension that leads to the breakage of the container. Glass is a bad heat conductor and therefore it does not tolerate excessive changes in temperature. Normally it can tolerate a variety of 45°C, so if, for example, it is necessary to reach the temperature required for pasteurization, 90°C, it is necessary to gradually increase the temperature of the environment where the container is situated. This method will prevent any problems even with the sterilization process, which reaches 130°C. It is necessary to use an even more gradual procedure for containers of a particular shape (jars with handles, sharp edges, extra large containers, etc.).

At what temperature does glass “break?”

None of the temperatures generally used in daily life cause glass to break. Glass may break at low temperatures, but this is because the contents freeze and their expansion cause the glass to crack (if the cap does not come off). Hot temperatures can cause the glass to break when the bottle is subject to excessive thermal variations. On the other hand, if a glass container is placed on a very hot source of heat (500°C for example), it can gradually lose its shape and change from a permanent solid form to a plastic state.

Can glass containers be filled with hot products as well?

Yes, they can. For instance, fruit jams are poured into glass pots at about 85°C. The problem is the difference between the temperature of the glass and the temperature of the product.

Glass containers should be adequately “acclimatized”: it is recommended that they are not moved from the warehouses (that are generally unheated) directly to the filling plant. Careful attention should also be paid to the subsequent heat treatments when the containers are sealed (pasteurization and sterilization), since these treatments influence the internal pressure.

What is the difference between cosmetic glass and glass for food products?

The difference lies essentially in the use of specific raw materials in the mixture which tends to favor products that enhance “shine” (by using barium for example) rather than the mechanical features. In cosmetic packaging, nickel alloy cast iron is used for the molds, in order to increase the glossy finish of glass containers.

What does “shatterproof glass” mean if the glass then breaks?

This is a “current” term which is not completely accurate. It refers to glass that has undergone a particular process called “tempering”, which brings the object to a temperature of about 600°C and then cools it suddenly (with cold air distributed according to the thickness of the glass), causing controlled raised tensions inside the object. In practice, a layer of tensile stress is created, bounded by two layers of compressive stress, giving the object increased resistance. The molecular structure which is created allows the glass to shatter into very small particles in the event of a sharp impact, and these cannot cause damage.

Why does a white film sometimes appear on glasses and bottles?

The cause of this white film is the humidity that is present in many environments and that creates a thin film on the surface of the containers. This film tends to draw out alkalis (sodium and calcium) from the surface of the glass, increasingly over time, until the contact liquid has completely evaporated. The resulting cloudy look is caused by the formation of carbonates due to the presence of Co2 in the air. It is usually enough to wash the glass or fill it and this film immediately disappears. It is important to note that this is just an “aesthetic” defect that doesn’t affect the use of the container and doesn’t cause any damage to the product inside. If glasses are unused for a long time and are kept in damp environments (in holiday homes for example) or after prolonged use, this process of extraction can become almost irreversible, with the accumulation of large quantities of insoluble calcium carbonate. This may result in a cloudy, rough surface caused by micro-abrasions and insoluble calcium deposits (a defect that is visible but harmless in terms of health).

Should a glass container be washed before filling it for the first time?

When a glass container reaches the warehouse after production, it is clean because all the production phases guarantee this feature. Nevertheless, since the openings of the jars and bottles sometimes remain in contact with the packaging materials for quite a long time and condensation may form, the operator responsible for the final packing of the product before it is actually filled generally carries out an inspection using special equipment. The container is often turned upside down and blown with compressed air, or in other cases a precautionary wash is carried out with steam that is then powerfully aspirated in order not to leave any residue.

Can the decoration or application of a frosted finish on a bottle be harmful for its contents?

These operations are only harmful if the interior of the bottle mouth is not kept adequately protected during the procedure.

Is there a special process for making beer bottles?

Beer Bottles that are especially designed for classic or craft beers (with fermentation in the bottle) are not manufactured using particular technical features except for the resistance to pressure, since – as for the champagne method – they must resist up to 6 bar. They are generally made in amber or dark green glass for better protection from UV rays.

Why are most beer bottles brown?

In the early days of bottled beer, it used to be packaged in clear glass. With time, however, after being exposed to sunlight, the taste of the beer would be found to be “skunky. The reason for this was the UV light rays that would alter the flavor. This made the bottles to be switched to brown and green.

Why is dark glass used for red wine?

The practice of using dark bottles for red wine has a lot to do with tradition; it has been a practice for a very long time. At the same time, it has a lot to do with protecting the contents from the effects of direct sunlight, which can affect the taste and the aging process.

What causes the “waves” that are visible around the lower circumference of a clear glass bottle?

These waves are left by the “parison” caused by the different temperature of the blank mold at the points where the glass ends after the gob is loaded. Careful adjustment of the production equipment certainly helps to prevent this optical effect (that is even more visible on clear glass bottles).

Today progressive pressure valves are used to limit this inconvenience. Once the bottle is filled, 90% of the optical effect disappears and the mechanical strength of the bottle is not affected. Other shadows on the body of the bottle may be caused by the incorrect loading of the glass gob.

Why do bottles have the same capacity but different glass weights?

This is due to different manufacturing requirements, for example the shape of a bottle may require a higher quantity of glass (e.g. for edges) or the use of the bottle may require a higher mechanical strength (for carbonated drinks or champagne), or to marketing purposes, because a heavier bottle appears to be more valuable or because the thickness of the glass can result in different shades of color.

How is glass color changed?

The color can be changed through a progressive but rapid change in the glass batch or by adding colorants. Obviously it takes a few days to clean the whole furnace from the previous color, since the molten glass mass amounts to about 100-300 tons depending on the furnace surface. Moreover glass has a slight elliptical movement and this causes the formation of pockets of resistance in corners of the furnace to the glass whose color is to be changed, which is also due to slight temperature variations in those positions and therefore different levels of viscosity.

It is also possible to color glass directly in the feeders, but in this case the feeders need to be specially designed so that they are the correct length to condition and homogenize the glass properly after the introduction of the “frit” (flakes of colorant material). In this way, it is possible to use clear glass on some machines and colored glass on other machines without having to change the contents of the whole furnace. In any case, this is a complicated and quite expensive procedure and only permits a limited range of colors.

Is there any particular difference between blue glass and green glass?

There is not much difference in terms of composition and function when it comes to blue and green glass. The colorants used are what differs between the two. Chromite is used for blue glass and cobalt for green glass. In terms of functionalities, UV filtration is higher in green glass compared to blue glass.

Why are glass jars generally vacuum-sealed?

Glass jars are vacuum-sealed in order to extend the preservation period for the contents (shelf life). There are three different methods of vacuum-sealing:

- mechanical or dry vacuum-sealing: using bell jars connected to pumps which remove the air (mainly for dry products).

- steam vacuum-sealing: this is the most commonly used system. A steam jet is injected into the container before sealing it;

- venting vacuum-sealing: once the jar has been filled with the product, it is closed in a tunnel or autoclave; a controlled increase in temperature allows the release of the air contained between the product and the lid.

There is another method which is currently used in households to pack products (e.g. fruit jam) which consists in filling the pot with the very hot product almost up to the brim with no empty space left at the top. When the pot is closed, the product cools down and automatically creates a vacuum seal.

Is it safe to reuse glass food jars?

Yes. Glass jars used for storing food are safe for reuse and can be repurposed indefinitely. The only thing you will need to do is to clean them thoroughly between uses. Another thing you need to be careful about are the lids. Lids once opened cannot be used to preserve canned food again, but can be used to cover jars storing other dry foods.

Why shouldn’t lids be re-used?

Because the mastic used for the lid, the material which allows the “air-tight” seal, doesn’t have the same elasticity after the first use. The “threads/lugs” that ensure the coupling of the lid to the jar finish become deformed after the first use.

What are the small dots on the bottom of a bottle for?

The sequence of space and dots represent a mold code number and they allow electronic control of the production process and of that particular mold.

What is the reason for the stippling on the bottle base?

The stippling helps to keep the bottle stable on the conveyor belt during production and to keep the bottle punt (which is still at 650°C) separate from the metal belt, preventing cuts to the bottle base through contact with different temperatures.

What are the engravings (letters and numbers) on bottles for?

They represent a sort of identity document for the bottle: they contain the name of the producer with its factory trademark, the brim capacity and the filling level, the number of mold cavities used to produce the bottle, and the symbol which indicates that the bottle/jar is suitable for food products.

- nominal capacity in cl or ml

- symbol for measuring container bottle*

- filling level

- bottom with dots

- symbol indicating it is suitable for food

- manufacturer’s trademark

- reference cavity number

- bottom with crescents

What is the “headspace” in a bottle or jar? Why can’t jars be filled to the brim?

Independently from the filling method, head space is necessary to allow the expansion of the liquid contained, caused by variations in temperature. The percentage of head space compared to the volume of the container must be calculated according to the filling method and also according to the type of content.

What is Type III glass? Are there other types of glass?

This is a classification of glass for containers which has been adopted by different Pharmacopoeias in order to establish a more appropriate use of glass in containers according to their contents. There is glass type I, type II and type III.

Type I is a borosilicate glass (known as Neutral) with a high hydrolytic stability suitable for containing injectable products.

Type II derives from type III: thanks to a special ammonium sulfate treatment of the internal surface, this type achieves a similar hydrolytic stability to type I and is suitable for containing acid or neutral products (e.g. infusion solutions).

Type III is a soda-lime glass with a low alkali content and good hydrolytic stability, suitable for containing preparations that are not in aqueous or alkaline sensitive solutions.

There is another type of glass which is suitable for containing food products and known as Type A Glass (soda-lime glass) which does not require any specific hydrolytic resistance, unlike type III.

Conclusion

Glass bottle packaging is part of our daily lives. There are endless questions in regards to glass containers, more than we can cover in this section. The ones we have been able to complete include the most common issues that people may have encountered. Are you looking for glass bottles and jars? With such a variety of glass bottle manufacturers, it is not easy to find your best glass bottle supplier. We are one of the leading glass bottle manufacturers in China, providing over 8000 styles of glass packaging ready for shipments. If your desired glass bottles not on the list, custom glass bottle is available.