Glass bottle packaging is eco-friendly, environmental, recycled and sustainable, which plays an important role in food and beverage industries, also in cosmetic beauty industries, as well as pharmaceutical and medical sectors. Cooperating with a reliable and experienced glass bottle manufacturer will avoid many packaging issues and making your glass bottle containers attractive in appearance and feeling.

Many companies prefer glass packaging material not only for the reason glass bottles are stable, non-active with content inside, but also glass packaging is beautiful, flexible and creative appearance. Glass packaging is the guide of consumer decision-making, which means package will effectively promote brands. For consumers, there are various options on the shelves. It is necessary to learn how to catch their attention, and guide them to buy your brands. Apart from the brands themselves, attractive packaging design is the key factor to win the crowd.

In this article, we will collect and share the most popular 6 surface decorations for glass bottles and jars, please read on and you will get the ideal decorating and labeling for your glass packaging.

Table of Contents

ToggleMethod 1 - Silk Screen Printing

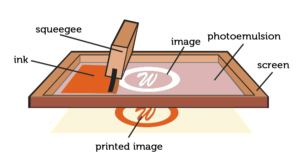

Silk screen printing is a special decoration for glass bottles and jars, which was invented more than 100 years ago, and involces placking ink on the surface of the glass through a mesh screen. It is a traditional and tested method of glass printing. This brand decor is made by printing a layer of ceramic ink on the surface of glass through the screen mesh. Once the ink has been applied to the glass, the glass and ink are fired to allow the ink to adhere firmly to the glass. As a result, silk screen printed glass is durable, scratch-proof, solar shading and with anti-glare effect.

Though silk screen printing will created an image that is clearly visible from a distance, and you will receive highly durable prints on the glass, this method is limited to just one or two colors design artwork. Honestly, this will consuming more time. Brand images with multiple colors require a different screen for each color, and the glass must be fired each time a new color is added to the printed image. This process is time-consuming and is prone to registration and coloration errors. On the other hand, screen for each color will add the cost. Therefore, the silk screen printing method may shackle down your creativity, limiting your flexibility to create the most ultimate designs.

According to our experience for decorations of glass containers, silk screen printing is the best option for single brand design, at most two colors. If your brand designs are full colors, please skip silk screen printing. Here we have a perfect printing method for multiple colors brand designs–decal printing.

Method 2 - Decal printing

The decal printing is very different from normal label sticker. We use the term “label” to describe adhesive products printed on papers or foils with inks not suitable for outdoors. Labels are tended to be supplied on a roll or sheet for use on packaging.

However, decals is often used for outdoor products. It is more associated with a ‘transfer’ from one medium to another. Decal is short for ‘decalcomania’ and usually is a more decorative type design. Therefore, ‘slide-on transfer decals’ or water-slide ceramic decals (transfers) for tile and ceramic uses are an accurate use of the decal term.

Decals are usually made from plastic, paper or vinyl. Depending on the type of decal, they can be applied to a wide range of substrates such as plastics, wood, coated metals, glass, painted products, leather, fabrics and rubber. These are for long term outdoor use and are supplied with a pre-masking sheet, so upon application are transferred from one sheet/medium to another. Unlike a traditional “sticker” which is removed from its backing paper and stuck where-ever, these decals are being transferred (often in multiple pieces) from the masking sheet to a smooth surface. Normally decals will have three layers: paper on the back, the decal itself, and paper on the front.

One of the greatest advantage of decal paper printing on glass containers is the ability to produce full colors printings at one time, seamless full-wrap graphics and photos. Unlike the silk screen printings which requires a different screen for each color and the glass container must be fired each time a new color is added to the printed image. With decal printing, brand images with multiple colors can be applied to the glass containers, then the glass containers and inks are fired to allow the inks to adhere firmly to the glass containers. No matter how many colors of your brand images, the glass containers with inks only need to be fired once. This process is time-saving and cost-saving, at the same time there is no limits for the colors of your brand image.

We have to admit that colorful and creative brand designs will get consumers’ attention, and effectively guide their decision-making. Therefore, decal printing is the perfect method to apply your brand images with multiple colors to glass containers.

Method 3 - Spray Coating ( 360℃ painting and gradient painting )

Spray coating is a fantastic method which will make your products eye-catching. The large amount of glass containers are clear and transparent color originally, or ordinary blue, green, amber colors, no special or attractive colors for consumers. Thus, many companies will choose spray coating on glass containers in order to set their goods from competitors. The main principle of glass coating involves thin-film optics. The desired reflection color and heat reflection function can both be achieved by adjustments in the thickness of the film. The interference effect of the film in the visible spectrum is utilized when using the infrared reflection performance of certain film material. There are a great variety of colors available for spray coating method, including black, white, blue, green, red, gold and more.

Apart from the variety of coating colors, you can achieve the desired coating effects, mainly including obscure ink coating, translucent ink coating, transparent ink coating. Gradient coating is enjoyed by more and more consumers. Matte or glossy can also be specified. Despite being robust, glass containers with spray coating can’t resist heavy usage or dishwashers.

Method 4 - Frosting

Frosting glass is the process of changing the surface of the glass from 100% transparent to translucent to create an opaque, cloudy look. This is usually achieved by acid-etching method, which is made by etching the durface of transparent glass with acid, giving it a heavily blurred surface that is still allows light in.

Frosting glass bottles still have a smooth surface. Glass comtainers with frosting decoration will set your products more mysterious to consumers, and tempt consumers into being curious about your products.

Method 5 - Foil Stamping

Foil stamping, also known as hot stamping, is a process of printing that transfers pre-dried ink or metal foils onto a surface through the use of stamping dies or heated image molds. This is a novel technology that allows you to apply foil on glass containers. There is no doubt that hot stamping or foil stamping is one of the most expensive decorations for brand decors or customized packaging. The bottle is partially cured after being screen printed with sticky ink. The foil is then adhered to the glass using foil stamping equipment.

Method 6 - Labeling

Label is the traditional decoration to your glass bottles and jars. We use the term “label” to describe adhesive products printed on papers oe foils with inks not suitable for outdoors. When consideration various label materials, you need to keep the environment of the product in mind. Moisture, heat, oil, and other factors can all negatively affect the labels made from certain material.

Conclusion

We have to admit that the first thing customers will notice about your goods on the shelf is the packaging. But one thing will definitely grab their attention is the glass packaging decoration design. Decoration printings on your glass bottles and jars will set you products out from your competitors. What’s more, printings on glass containers will reflects product and brand. Consumers tend to perceive products in higher quality packaging to be of superior quality. The main principle of deigns that will be printed on glass bottles and jars should be considered to meed the four goals: attract the buyers, communicate your messages quickly and effectively, establish a desire to have the product, finally but most important to sell the products.

We are China glass bottle manufacturers, and we always spare no effort to make sure that we meet your needs to the highest satisfaction level. With your brand design ideas, we will dedicate to ensuring the best and suited printings to your glass bottles and jars. You are welcome to get in contact with us immediately!