Glass container are used frequently in our daily life, very common and easy to get. Comparing to other types of packaging for food and beverages, like plastic, glass bottles have many advantages. Glass packaging is eco-friendly, environmental, healthy, and reusable. Glass bottles and jars are made of 3 main materials, silica sand, soda ash and limestone, no chemical contents, thus glass packaging will not leak harmful gases or ingredients into your food and beverages, very safe. Need to buy glass packaging from experienced glass bottle manufacturer in China, we are at services.

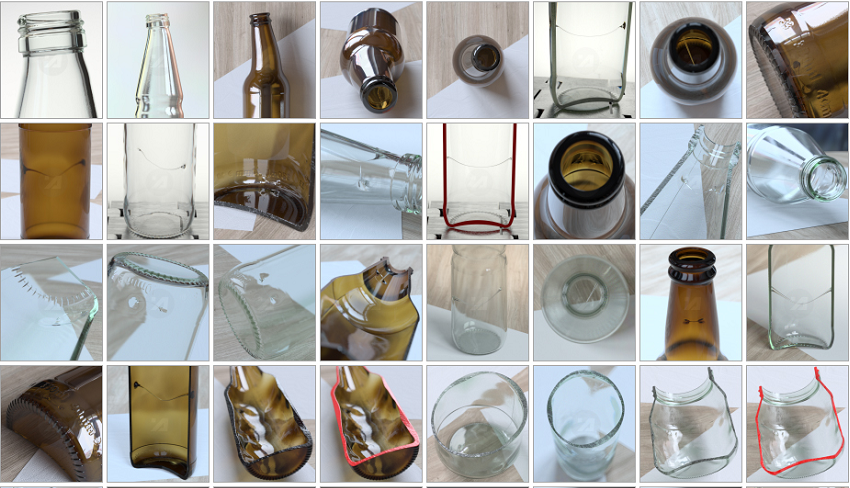

Although glass bottles and jars are recycle and reused, there are many defects needed to be avoided in the process of glass production.The common science is that glass defects are typically unavoidable, but their occurrence must be minimized during the production or high-quality glasses. Common glass defects include bubbles, stones, knots, cords and cat scratches etc.

Below are a list of Critical and Major defects that can occur during production of promotional glass bottles:

Table of Contents

ToggleCritical Defects

- Stuck Plug. A piece of glass, usually very sharp, projecting inwards just inside the neck bore.

- Overpress. Is a defect where a small ridge of glass has been formed on the sealing surface of the finish.

- Split finish. A small vertical crack starting at the top of the finish and going downwards. This defect is difficult to detect because it does not reflect light.

- Check. A small, shallow surface crack, usually at the bore of the container.

- Freaks. Odd shapes and conditions that render the container completely unusable. Bent or cocked necks are a common defect of this type.

- Poor Distribution. Thin shoulder, slug neck, choke neck, heavy bottom are terms used to describe the uneven distribution of glass.

- Soft Blister. A thin blister, usually found on or near the sealing surface. However, it can show up anywhere on the glass container.

- Choked Bore. Excess of glass has been distributed to the inside of the finish or opening.

- Cracks. Partial fractures, usually found in the heel area.

- Pinhole. Any opening causing leakage. It occurs most often in bottles with pointed corners.

- Filament. A hair-like string inside the bottle.

- Spike. Spikes are glass inside the bottle.

- Bird Swing. Glass thread joining the two walls of the container.

Major Defects

- Chipped Finish. Pieces broken out of the top edge in the manufacturing process.

- Stone. Small inclusion of any non-glass material.

- Rocker Bottom. A sunken centre portion on in base of the container.

- Flanged Bottom. A rim of glass around the bottom at the parting line.

Critical Defects and Remedies

| Critical defects | Description | Problems | Remedies |

| Stuck Plug | Unwanted pieces of glass, which may or may not be sharp, stuck to the external surface of the item. | It may affect filling and packing. | Decrease glass or plunger temperature Tighten the plunger adaptor to the rod of pistonIncrease the exhaust hole size Change the plunger Optimize cooling air flow to plunger |

| Overpress | A finish which has excessive glass projecting upward from the inside edge of the finish. This is a critical defect in all types of finish. | Defective closure, risk of leaks, product deterioration Breakage of the overpress with risk of contamination | Adjust gob temperature Shorten plunger contact time Change neck ring Dehumidify blow air Optimize mold closing time/speedIncrease gob weight or modify shape |

| Split finish | A small vertical crack starting at the top of the finish and going downwards. This defect is difficult to detect because it does not reflect light. | Breakage of the article during or after filling and packing Risk of accidents due to bursting if used with a carbonated product. | Adjust gob temperature Shorten plunger contact time Change neck ring Dehumidify blow air Optimize mold closing time/speedIncrease gob weight or modify shape |

| Check | Small crack running from the top of the finish in a downward direction. It can be seen by looking at the light reflection while turning the bottle. | Risk of breakage during packing (corking, sealing). | Adjust gob temperature Shorten plunger contact time Change neck ring Dehumidify blow air Optimize mold closing time/speedIncrease gob weight or modify shape |

| Freak | Article is malformed, warped or completely sunken. | Impossible to pack the item properly. | Correct set up parameters |

| Poor Distribution | The thickness of the glass does not meet the specifications. | Risk of breakage if knocked during transport or packing. | Decrease glass temperature Eliminate glass temperature differences Decrease the gob shapeLoad correctly the gobIncrease hardness of parison |

| Soft Blister | Broken or unbroken bubbles in the thickness of the glass on the finish. | cracked > the surface is broken not cracked > with a thin skin | Dehumidify blow air |

| Choked Bore | Excess of glass in the neck which partially or completely obstructs the bore and doesn’t allow the filling tube to be introduced. | The container is not suitable for use, risk of breakage during filling, deterioration of contents. | Feeder Set temperature of forehearth so that the gob does not curl Adjust gob shape Machine Setup and Operation Retard the counterblow Advance counterblow and cool the glass Reduce plunger cooling airReduce plunger contact time Fit drip pan to the deflector Balance the cooling air on the two mold halvesIncrease blank cooling and swab as required Change plunger and/or neck ring Mold Equipment Adjust plunger design Correct size of take-out tongs Take .002 increments from nose of plunge |

| crack | Increase glass temperatureIncrease machine speed Stabilize Leher temperature | ||

| Pinhole | The finish is not completely regular; the thread profile has not been formed properly. There is glass missing from the top surface. | Defective sealing: risk of leaks, product deterioration, problems in vacuum filling.Sometimes this can be just a minor defect (m), for instance unfilled finish on the bead of a cork mouth. | Adjust gob temperature Shorten plunger contact time Change neck ring Dehumidify blow air Optimize mold closing time/speedIncrease gob weight or modify shape |

| Filament | Hair-shape string, numerous fine vertical marks, often on the shoulder. | Remove glass remains in flow head Reduce plunger time inlet Change shearsDecrease the speed of the machine Slightly delay the vacuum inlet Remove glass particles when mold is changed | |

| Spike | A projection of glass extending upwards from the bottom on the inside of the jar or bottle. More frequent in the “press-blow” process, and in containers with a broad mouth. | Remove glass remains in flow head Reduce plunger time inlet Change shears Decrease the speed of the machine Slightly delay the vacuum inlet Remove glass particles when mold is changed | |

| Bird Swing | A bird swing can occur both in the “press-blow” and “blow-blow” process. It is a thin strand of glass across the inside of a container either between the walls or between the wall and the bottom. | Remove glass remains in flow head Reduce plunger time inlet Change shears Decrease the speed of the machine Slightly delay the vacuum inlet Remove glass particles when mold is changed |

Tolerance During Glass Manufacturing

Tolerances are the allowed differences between individual glass products. In order to ensure production is consistent tolerances are set during manufacturing. Glass tolerances can be applied to most products. However, if the glass product has to fit inside a container e.g. aftershave and perfume bottles then the tolerances may need to be reduced.

Qaulity Management

Quality control reduces defects in production. Following the steps below results in the reduction of errors.

- Test bottles at regular intervals during production.

- If any bottle in the round fails testing, four additional bottles need testing.

- If a failure occurs among the four bottles tested then all bottles should be rejected until fault has been rectified.

- When all four bottles pass testing production can continue.

- After initial failure has been verified, all pallets loaded with bottles produced from the last unsatisfactory test are detained.

Conclusion

Soda lime glass bottle are made from a mold, which has two parts. So, the appearance of the bottle surface you can find the part line of the mold. When the mold is dirty or used many times, the bottle surface will be not so good looking. The mold material is alloy. The bottle-made process is complicated so find a qualified supplier can help you to focus on your product itself and the branding of the product. Custom glass bottles require expert knowledge to ensure a high quality product.

If you are in search of a better glass experience, fnding an experienced glass bottle manufacturer, supplier, we are your reliable China glass bottle manufacturer, well-knowing glass bottle production and avoid quality defects during glass production process. Bespoke moulded bottles are available, unique decorations for your glass packaging at affordable prices.